Innovative Drone Technology Revolutionizes 3D Printing

Written on

Chapter 1: Nature-Inspired 3D Printing

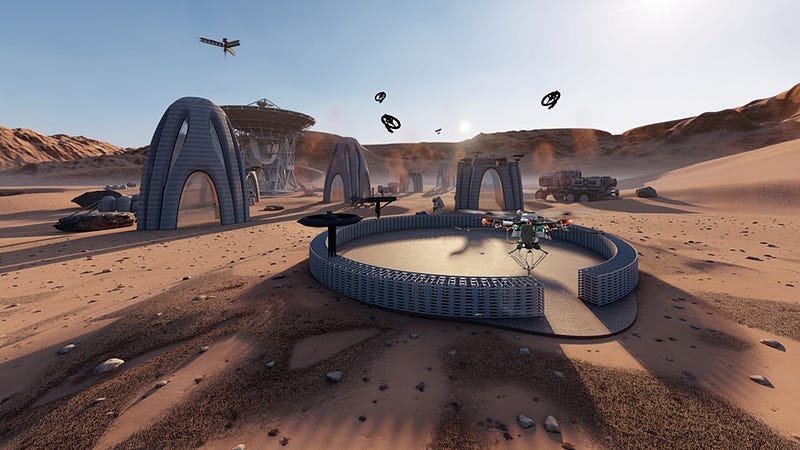

This article delves into the transformative potential of collaborative drones in the realm of construction. These advanced machines are set to revolutionize building and repair processes, even in the challenging environments of Mars.

“The future of 3D printing is here, driven by innovative technology inspired by nature.”

Section 1.1: Aerial Additive Manufacturing

The Aerial Additive Manufacturing (Aerial-AM) system, developed by researchers at Imperial College London and Empa, draws inspiration from the collaborative behaviors of wasps and bees. This groundbreaking technology enables a swarm of drones to work together based on a single blueprint, enhancing efficiency and precision in construction.

Subsection 1.1.1: The Role of BuilDrones and ScanDrones

The Aerial-AM system is comprised of two distinct types of drones: BuilDrones and ScanDrones. BuilDrones are responsible for material deposition during flight, while ScanDrones monitor the output and provide feedback for the next steps in the construction process. This dual-drone system ensures quality control and precision throughout the manufacturing phase.

Section 1.2: Potential Applications

The implications of Aerial-AM extend far beyond Earth. This innovative technology could facilitate rapid rehabilitation in disaster-stricken areas and even support construction efforts in outer space, paving the way for habitats on the Moon and Mars.

According to Professor Mirko Kovac, the lead researcher, "We’ve demonstrated that drones can operate autonomously and collaboratively to construct and repair buildings, at least in a laboratory setting. This scalable solution could be invaluable for construction in hard-to-access regions, such as high-rise buildings.”

Chapter 2: Advancements in Real-Time Adaptation

The first video showcases the groundbreaking capabilities of 3D printing with drones, emphasizing their potential impact on future construction methods.

As these drones operate autonomously, they are also equipped with a human-controlled interface for addressing any issues that may arise during operation. In preliminary tests, researchers developed four cement-like mixtures to evaluate the system's effectiveness. Impressively, the drones consistently assessed the printed structures in real time, allowing them to adjust their actions to meet specific construction requirements.

This system successfully produced a 2.05-meter-high cylinder with 72 layers using a polyurethane foam material, as well as an 18-centimeter-high cylinder with 28 layers made from a specially designed structural cement-like substance. The research team aims to expand their proof of concept into commercial applications, focusing on scaling the system and achieving significant cost savings while minimizing risks compared to traditional construction methods.

The findings from this comprehensive research were published in the Journal of Nature.

The second video explores the fascinating concept of wasp-inspired drones capable of 3D printing entire buildings, showcasing the future of construction technology.